Case Study: Supply Chain Strategy for a Consumer Electronics Company

Focusing on Transportation in Developing a New Supply Chain Strategy

A multi-billion dollar manufacturer of consumer electronics products needed to refine its supply chain strategy. The initial phase of the project was to understand how their supply chain costs compared to their direct competition within the industry in order to prioritize the areas of the supply chain on which to focus.

An initiative was developed and introduced by Establish to benchmark the client’s supply chain costs by product category and supply chain component. Establish gathered cost data from a target group of the client’s direct competitors and developed a comparison group for the initiative that represented over 80 percent market share for each of the selected product groups.

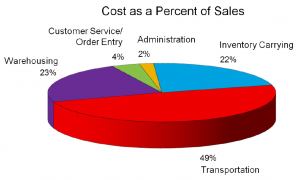

By directly comparing our client’s supply chain costs to those of direct competitors, it became obvious that the transportation component of the supply chain was not only the largest in terms of spend, but the most “out of sync” with the comparison group.

The initial project originating from the benchmarking initiative was to identify what the underlying reasons were for the transportation spend, and then to identify savings opportunities that would both reduce the spend while maintaining or improving carrier delivery performance.

Then, extensive data was gathered on the shipment modes, lanes (origins and destinations), customer delivery requirements and current carrier performance levels, carriers preferred, the tendering processes, carrier handling processes, carrier claims, etc.

Several opportunities were developed through the data analysis, observations and modeling that could both reduce costs, as well as improve the delivery performance.

The first project following the benchmarking initiative was to reduce the number of carrier claims by making changes to the product packaging, labeling, tendering processes, and the carrier documentation requirements. These changes not only improved customer service performance levels, but ultimately facilitated subsequent carrier rate negotiations.

After establishing carrier negotiation targets for rates and fuel surcharges, the negotiations commenced and the end result was a reduction in the client’s annual transportation spend of 10 to 12 percent. The improved packaging and the potential reduction in claims were critical negotiation factors.

The project from the initial review of client’s supply chain costs was the reconfiguration of the client’s supply chain network that included changes to the physical location where products were stored and shipped. This reconfiguration not only included both the physical movement and consolidation of some existing facilities, but also a change to the product flows through that network.

Through the product packaging improvements, rate negotiations and network optimization, Establish was able to assist the client in reducing the supply chain spend with 15%.

Establish is a supply chain consulting firm focusing on supply chain strategy, 3pl management, warehouse design & improvements and supply chain planning.